Understanding the Parts of Your Milling Machine

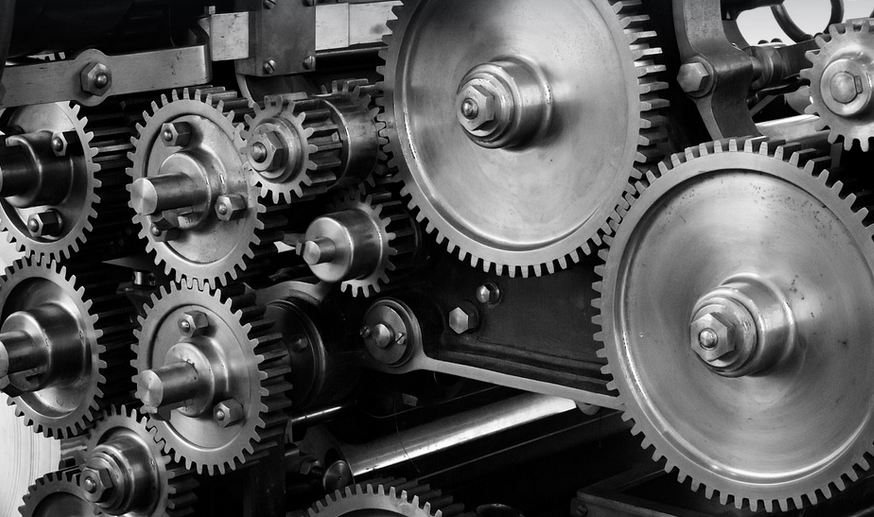

Welcome to the world of milling machines! These incredible tools allow us to create precision shapes and cuts in a wide range of materials. Whether you’re a seasoned machinist or just starting out, understanding your machine is key to unlocking its full potential.

Just like any complex piece of machinery, a milling machine consists of several vital components that work together in harmony. Let’s take a tour through the different parts of this fascinating machine and learn what each plays a role:

1. Table: The Foundation of Your Work

The table is the platform where your workpiece rests, often with a movable slide to accommodate various materials and tool positions. Its size, rigidity, and adjustability are crucial for precision cutting and holding workpieces securely during operation.

**2. Spindle: The Cutting Powerhouse

The spindle is the heart of any milling machine, housing the motor that spins the cutting tool at high speeds. It typically has a threaded chuck or collet system for securing workpieces securely and allows for precise speed control to ensure smooth cuts.

**3. Motor: The Driving Force

The motor is responsible for providing rotational power to the spindle. It’s often combined with the controller, enabling precise speed adjustments based on your work requirements and desired results. Selecting a suitable motor according to the cutting load is vital for optimal performance.

**4. Feed Rate System: The Movement Control

The feed rate system controls how fast or slow the spindle travels down the workpiece path. This component’s accuracy ensures consistent cuts and smooth operation, with features such as preset speed settings for frequent use.

**5. C-Clamp or Vise: The Secure Hold

These clamping devices firmly secure your workpiece to the table during machining. You can choose between C-clamps and vises depending on the size of the workpiece, project complexity, and desired level of precision.

**6. Tool Holder: The Cutting Tool’s Cradle

The tool holder is a crucial component that securely holds your cutting tools and connects them to the spindle. Each tool requires specific holders to ensure proper alignment and efficient operation, ensuring optimal performance and longevity.

**7. Chuck or Collet: The Secure Grip

The chuck is a rotating component that securely grips the work piece with a variety of sizes and styles available for different applications. It allows for quick workpiece changeovers, enabling efficient use and versatility.

Understanding Milling Machine Components in Detail

Let’s delve into a few more specific parts:

**1. Spindle Bearings: The Silent Workhorses

The spindle bearings are the crucial components responsible for holding the weight of the rotating spindle and allow it to smoothly move. Their proper lubrication ensures smooth operation, reducing friction and wear.

**2. Gearbox: The Speed Control Master

The gearbox is used in some millers to change the speed of the spindle. This offers a range of speeds to accommodate different materials and cutting requirements.

**3. Coolant System: The Heat Control Crew

A milling machine’s coolant system keeps things running smoothly, especially when machining hard or heat-generating materials. It helps prevent overheating of the workpiece and cooling down the tool during use.

**4. Electronic Controller: The Digital Brain

The electronic controller is the brain of your milling machine. It receives commands from your user interface, manages tool changes, speed control, and ensures safe operation.

As you can see, each part of a milling machine plays a vital role in creating precision cuts and achieving desired results. While understanding basic mechanics might seem challenging at first, with the right guidance and practice, you’re well on your way to mastering this powerful tool!